CUSTOM MACHINING TRANSFER FINGERS IN CANTON, MI

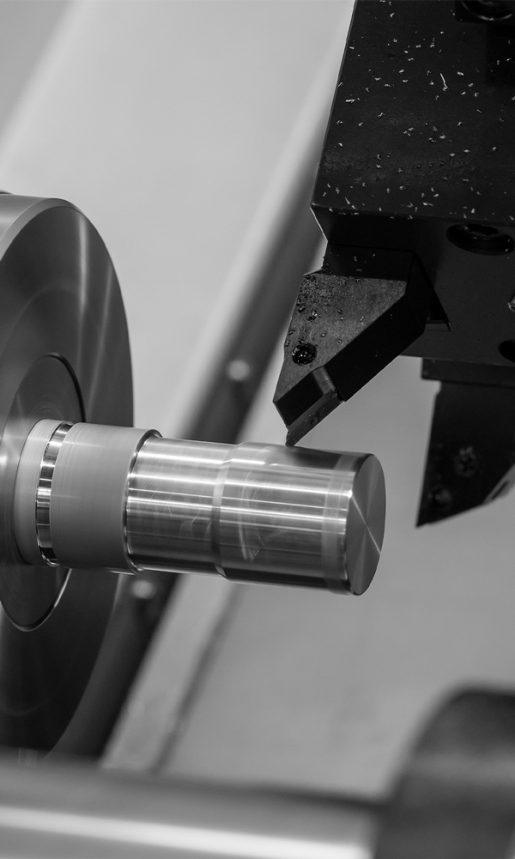

Transfer fingers, also known as transfer pads or fingers, are essential components in machine tooling used for transferring workpieces between different stages of machining processes. These fingers are typically made of durable materials such as steel or carbide and are designed to securely hold and manipulate workpieces during automated operations.

In machining applications, transfer fingers play a crucial role in ensuring smooth and efficient workflow by accurately positioning workpieces for forming operations such as milling, drilling, or grinding. They are often integrated into robotic or automated systems to facilitate the transfer of workpieces between machining stations or conveyor systems.

Transfer fingers come in various shapes and sizes to accommodate different types of workpieces and machining requirements. Some may have specialized features such as adjustable clamping mechanisms or interchangeable inserts to provide versatility and adaptability to various production setups. The design and configuration of transfer fingers depend on factors such as the size and weight of the workpieces, the required precision of positioning, and the specific requirements of the machining process. Proper selection and integration of transfer fingers are essential for optimizing production efficiency and ensuring consistent quality in machine tooling operations.